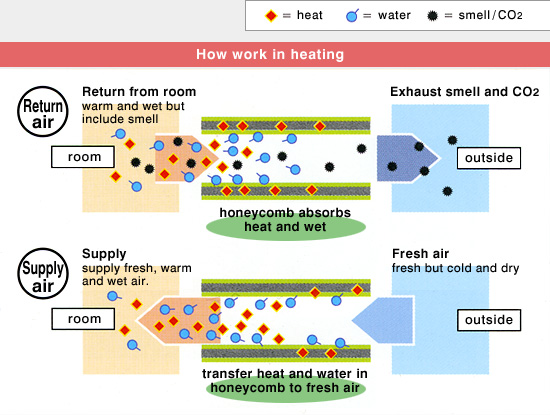

Total Heat Exchanger is the product by which recover the total heat (sensible heat and latent heat) wasted during air conditioning ventilation, and perform quite effective energy saving. But, usual total heat exchanger use zeolite and silica gel as absorbent material, and have the problem of transferring VOC and smell into the fresh air.

However, our ion adsorption type total heat exchanger solved this problem, and it make it possible to use it as energy recovery system for room air conditioning, local exhaust air from printing or converting factory contained VOC and exhaust air from clean room.

However, our ion adsorption type total heat exchanger solved this problem, and it make it possible to use it as energy recovery system for room air conditioning, local exhaust air from printing or converting factory contained VOC and exhaust air from clean room.

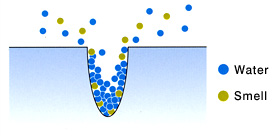

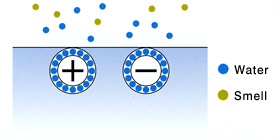

VOC and smell transfer prevention effect

absorption by silica gel

Because of adsorption by capillary method, smell is also adsorbed together with water.

Especially it is remarkable in water-soluble-smell

Especially it is remarkable in water-soluble-smell

Absorption by ion

Adsorb only water molecules as ions characteristic.

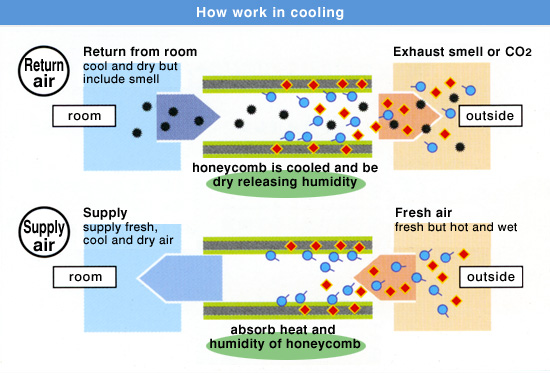

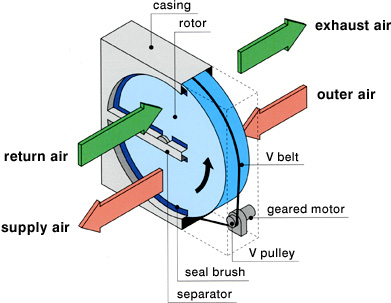

Principle of total Heat Exchanger

Structure

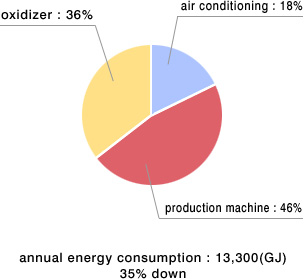

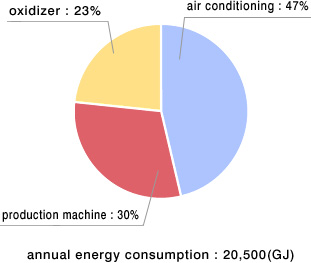

Breakdown of energy consumption for Gravure printing factory

To keep the environmental standards for labors, gravure printing factory must exhaust large volume of air from the factory for air conditioning and local air emissions. In result, it needs to take fresh air into the factory from outside, and it is said that 50% of the total energy are consumed for air conditioning in the factory.

Therefore, reduction of air conditioning load is the issue not avoided for energy saving program.

Ion adsorption type total heat exchange can reduce air conditioning load in the factory.

Energy consumption in the gravure printing factory

with 4 printing presses

with 4 printing presses

Energy consumption after installation of

total heat exchanger

total heat exchanger